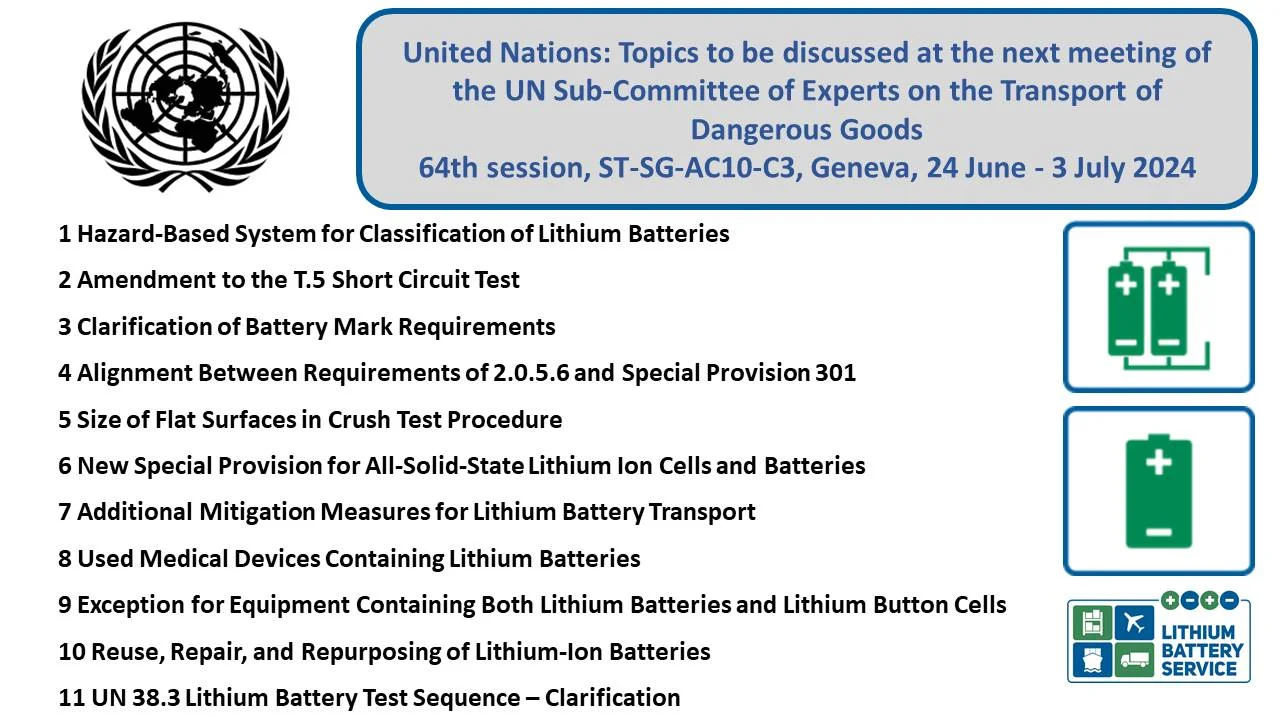

United Nations: Topics to be discussed at the next meeting of the UN Sub-Committee of Experts on the Transport of Dangerous Goods 64th session, ST-SG-AC10-C3, Geneva, 24 June - 3 July 2024

Here an overview and summary of the topics on lithium cells and batteries and on sodium cells and batteries that will be discussed.

Here an overview and summary of the topics on lithium cells and batteries and on sodium cells and batteries that will be discussed. It is quite time consuming to download all the complete papers from the UN ECE website so if you want to save time just send us an email and we´ll provide you with a ZIP file including all the proposals mentioned here.

1.1 Hazard-Based System for Classification of Lithium Batteries (Document ST/SG/AC.10/C.3/2024/13)

- State and Organization: Transmitted by the experts from Belgium and France and by the Advanced Rechargeable and Lithium Batteries Association (RECHARGE) on behalf of the informal working group.

- Introduction: There's a need for a more detailed hazard-based classification system for lithium batteries to improve safety and regulatory compliance. The current system does not sufficiently differentiate between various types of lithium batteries and their specific hazards.

- Proposal: Develop a new classification system with multiple hazard categories and corresponding UN numbers for lithium and sodium ion batteries. This system aims to better reflect the varying hazards posed by different battery types. It will also facilitate the development of more targeted safety measures and transport conditions. The proposal includes detailed testing protocols and classification criteria to ensure accurate hazard assessment.

1.2 Amendment to the T.5 Short Circuit Test (Document ST/SG/AC.10/C.3/2024/15)

- State and Organization: Submitted by the Advanced Rechargeable & Lithium Batteries Association (RECHARGE).

- Introduction: New battery designs, such as those for wireless charging, make it impossible to access terminals without dismantling the battery, complicating the short circuit test. This can hinder the verification of safety measures in place.

- Proposal: Allow a verification process for these batteries, where dismantling is performed following manufacturer guidelines to check the effectiveness of short circuit protection after tests. This change will ensure that even new battery designs can be adequately tested for safety. It will also align the testing procedures with the practical realities of modern battery designs. This proposal will help maintain high safety standards without compromising the integrity of new battery designs.

1.3 Clarification of Battery Mark Requirements (Document ST/SG/AC.10/C.3/2024/28)

- State and Organization: Transmitted by the experts from Canada and China.

- Introduction: The current marking requirements for lithium batteries in the Model Regulations are ambiguous, particularly in special provision 188. This ambiguity leads to inconsistencies in how lithium batteries are marked for transport, potentially compromising safety.

- Proposal: Amend special provision 188 to ensure it references all requirements under 5.2.1.9, not just the illustration, thus closing a regulatory gap and ensuring consistency. This change will make the regulations clearer and easier to follow for manufacturers and transporters. It will also enhance the overall safety of lithium battery transport. Ensuring clear and consistent marking will help in the proper handling and identification of lithium batteries during transport.

1.4 Alignment Between Requirements of 2.0.5.6 and Special Provision 301 (Document ST/SG/AC.10/C.3/2024/35)

- State and Organization: Submitted by the expert from China.

- Introduction: Inconsistencies exist between paragraph 2.0.5.6 and special provision 301 regarding the enclosure of dangerous goods. These inconsistencies can cause confusion and potentially unsafe transport conditions.

- Proposal: Amend both sections to ensure only dangerous goods that could react dangerously need separate enclosure, providing a more practical and safe regulatory approach. This amendment will make the regulations more coherent and easier to follow. It will also enhance the safety of transporting multiple dangerous goods in a single package. The proposed changes will streamline the regulatory requirements, reducing complexity and potential errors.

1.5 Size of Flat Surfaces in Crush Test Procedure (Document ST/SG/AC.10/C.3/2024/39)

- State and Organization: Transmitted by the expert from China.

- Introduction: The crush test procedure for large batteries is currently insufficient due to undefined surface dimensions. This lack of specificity can lead to inconsistent test results and potential safety hazards.

- Justification and Proposal: Specify that the surfaces used in crush tests must be larger than the battery's largest side to ensure accurate testing and safety. This change will standardize the testing process and improve the reliability of the results. Ensuring proper testing conditions is crucial for validating the safety of large batteries during transport. Standardizing surface dimensions in testing will prevent variances that could affect the test outcomes.

1.6 New Special Provision for All-Solid-State Lithium Ion Cells and Batteries (Document ST/SG/AC.10/C.3/2024/42)

- State and Organization: Transmitted by the expert from Japan.

- Introduction: All-solid-state lithium ion batteries, which do not cause thermal runaway, are not adequately addressed in current regulations. These batteries offer significant safety advantages that should be recognized in transport regulations.

- Proposal: Introduce a special provision for these batteries to simplify transport procedures and enhance safety, linked to sustainable development goals. This will involve setting specific criteria that these batteries must meet to qualify for the special provision. The new regulations aim to encourage the use of safer battery technologies while maintaining strict safety standards. Recognizing the unique safety features of all-solid-state batteries will promote their adoption and improve overall transport safety.

1.7 Additional Mitigation Measures for Lithium Battery Transport (Document ST/SG/AC.10/C.3/2024/45)

- State and Organization: Transmitted by the International Civil Aviation Organization (ICAO).

- Introduction: Following a safety risk assessment, ICAO recommended new restrictions on lithium battery transport, including state of charge limits. These measures aim to reduce the risk of incidents during air transport.

- Proposal: Include requirements for competent authority approval of testing laboratories and detailed quality assessments for manufacturers, including third-party verification. This will ensure that all testing is conducted to the highest standards, reducing the risk of transport incidents. The proposed measures will also promote better compliance with safety regulations.

1.8 Used Medical Devices Containing Lithium Batteries (Document ST/SG/AC.10/C.3/2024/51)

- State and Organization: Transmitted by the Council on the Safe Transportation of Hazardous Articles (COSTHA).

- Introduction: The current exemption for used medical devices does not include provisions for lithium batteries, complicating transport for disinfection and repair. This omission can lead to misclassification and safety risks during transport.

- Proposal: Amend 2.6.3.2.3.9 to include lithium batteries, allowing these devices to be classified under UN 3481 or UN 3091, facilitating safer and more efficient transport. This will provide clear guidelines for the safe transport of used medical devices containing lithium batteries. The proposal aims to enhance safety and streamline regulatory compliance for transporting these devices.

1.9 Exception for Equipment Containing Both Lithium Batteries and Lithium Button Cells (Document ST/SG/AC.10/C.3/2024/53)

- State and Organization: Transmitted by the International Air Transport Association (IATA).

- Introduction: Current regulations do not differentiate between lithium batteries and button cells in equipment, causing complications. This lack of differentiation can lead to unnecessary regulatory burdens and potential safety issues.

- Proposal: Amend special provision 188 and 5.2.1.9.2 to exclude button cells from counting towards package limits when transported with other lithium batteries. This change will simplify the transport regulations and reduce confusion. The amendment will help ensure that regulatory requirements are practical and do not impose unnecessary burdens on transporters.

1.10 Reuse, Repair, and Repurposing of Lithium-Ion Batteries (Document ST/SG/AC.10/C.3/2024/55)

- State and Organization: Submitted by PRBA – The Rechargeable Battery Association and Advanced Rechargeable and Lithium Batteries Association (RECHARGE).

- Introduction: Governments and NGOs promote a circular economy, encouraging the reuse and repurposing of lithium-ion batteries. However, this raises safety and regulatory concerns under UN 38.3 testing requirements. Ensuring safety during the repurposing process is crucial to prevent transport incidents.

- Proposal: Add a new provision in section 38.3.2.1 to address design changes from repurposing, remanufacturing, or repairing batteries, emphasizing the need for retesting if these changes might affect safety. This will involve setting specific criteria for what constitutes a significant design change. The goal is to maintain high safety standards while supporting sustainability initiatives. This amendment will help ensure that repurposed batteries are as safe as new ones.

1.11 UN 38.3 Lithium Battery Test Sequence – Clarification (Document ST/SG/AC.10/C.3/2024/56)

- State and Organization: Transmitted by PRBA – The Rechargeable Battery Association.

- Introduction: The sequence of tests T.1 to T.5 in section 38.3.4 is often misinterpreted, causing operational inefficiencies. Clarifying the sequence will help testing laboratories and manufacturers ensure compliance without unnecessary delays.

- Proposal: Amend the text to clarify that tests can be conducted out of sequence as long as cumulative stress is applied, with T.5 being the last test due to its destructive nature. This will allow more flexibility in the testing process, making it more efficient while maintaining safety standards. Adjusting the sequence will prevent delays caused by rigid testing procedures.