Feedback on our rephrasing proposal regarding the manufacture according to QM system

In our October newsletter we had mentioned the topic of the manufacture of lithium cells and batteries according to quality management program and also a reformulation proposal ...

...

or deletion of references, with which the responsibility

for compliance lies 100% with the manufacturer.

We received the following very clear description from Sebastian Roehler of VARTA Microbattery GmbH describing this

process and also an absolutely plausible explanation why using the word "Quality Management System" would make

more sense.

Here is the email with his explanations, which we are allowed to provide to you:

Von: "Roehler, Sebastian"

Betreff: AW: Newsletter Nr. 6-222

Datum: 20. Oktober 2022 um 16:10:08 MESZ

An: Eva Glimsche

Hello Eva,

Thanks for your feedback! You are welcome to publish it and name me. I have polished the wording for it a bit more:

The term "quality assurance" is no longer appropriate. Quality cannot be "assured". For a product to meet its quality

requirements, the quality requirements must be implemented in all phases of product development. The approach of

quality assurance was to check in downstream phases whether a product meets the requirements. However, this only

works to a limited extent. An example from the world of batteries: if a defect is built into a cell due to a poor production

environment, it cannot be detected by a quality inspection at the end of the manufacturing process. However, this

defect can later lead to a safety-critical failure of the cell. Such defects can be avoided by a quality management

system that keeps an eye on all risks and takes appropriate measures to mitigate them.

I therefore recommend that the term "quality management" be retained. What always irritates me is the "program" in

"quality management program". I have not encountered this term anywhere outside of the hazardous materials

regulations. In my opinion, it should be "quality management system". The international standard ISO 9001 describes

how such a QMS can be developed. Manufacturers who operate a system according to ISO 9001 would then not

have to additionally confirm that their "quality management system" is also a "quality management program".

More blog posts

Latest newsblog posts

How to Efficiently Recycle Li-ion Batteries

December 14, 2024

Ideas

| Knowledge

The article describes an innovative method for efficiently recycling lithium-ion batteries, developed by a research team at Rice University led by James Tour.

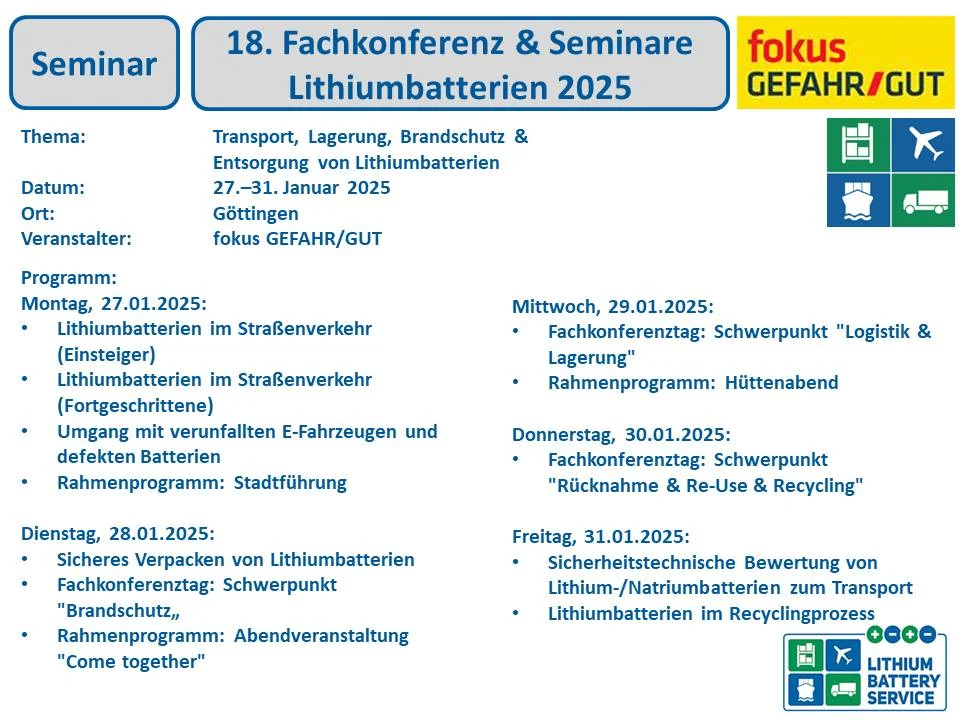

18. Fachkonferenz & Seminare: Lithiumbatterien 2025 Transport, Lagerung, Brandschutz & Entsorgung von Energiespeichern

December 9, 2024

Dates

| General

Die 18. Fachkonferenz Lithiumbatterien beleuchtet alle Aspekte der Batterielogistik – von der „Geburt“ bis zum Ende.

Promoting an open dialog on battery safety

October 18, 2024

Dates

Finding solutions to the root causes of battery safety incidents and convening companies from all parts of the supply chain to address the issue of battery safety is paramount.

Virtual Battery Day

October 18, 2024

Dates

After last year 's great success with around 1,000 participants, LUMITOS is once again organizing the virtual battery day on 13 November 2024.

How to Efficiently Recycle Li-ion Batteries

October 14, 2024

Knowledge

A research team at Rice University is tackling the environmental issue of efficiently recycling Li-ion batteries amid their increasing use.

Training dates and free question time for license customers

October 14, 2024

Newsletter

This is a good time of year to get up-to-date on changes, get into more details on certain topics and to take time to ask your questions and have them answered.

EV & ESS High Voltage Battery Pack Design Virtual Seminar

October 6, 2024

Dates

Shmuel De-Leon Energy, American Battery Solutions from the USA and Obrist Powertrain from Austria invites you to join 6.5 hours battery virtual EV/ESS High Voltage Battery Pack Design seminar.

4th USA EV & ESS Battery Design and Production Hands-On Seminar

September 29, 2024

Dates

EV battery market is growing dramatically as well as demand for EV battery design knowledge and best practice.

Validity UN38.3 test or UN 38.3 test summary

September 19, 2024

Newsletter

There is no expiry date for UN 38.3 tests or UN 38.3 test summaries. If you are asked for documents that are a maximum of 2 years old or for a current document from 2024, there may be a number of reasons for this.